Network model¶

Intro¶

The core element for the pressure model is the quadratic relationship between pressure loss over any length of pipe and the mass transport (flow), that passes through it:

where \Delta H is the pressure loss, α is a generalized form of the resistance exercised on the water and q \begin{bmatrix} \frac{m^3}{h} \end{bmatrix} is the flow. The term |q|q is colloquially referred to as the flow squared. The absolute term preserves information about the flow direction, so |q|q is positive if the flow is in the direction defined as positive, and negative if the flow runs in the opposite direction.

The calibration objective is to identify an optimal value for the pipe resistance, \alpha, in each pipe, given the assumptions (see below) about the model is satisfied.

The calibration procedure does not build the model. It requires, instead, a dataset of flow and pressure loss for each pipe to calibrate. It is expected that measured data will not be readily available in the locations of the desired model. Also, it is expected that measured data will be somewhat corrupted by various sources e.g., measurement uncertainty and water loss. The data handling procedures are designed to address these issues. The default usage of the model is to predict flow and pressure loss as an observation pair for each pipe.

Assumptions & requirements for a pressure model¶

The measured data should be processed to solve the following challenges:

- The rate at which data is collected is susceptible to measurement uncertainties and high frequency dynamics, that might not accurately represent the targeted model dynamics.

- The nodes in the model should align with locations of pressure measurements in the distribution network. The flow measurements, however, can’t cover each pipe (or edge in the model). So, a mass balance problem should be solved to populate the modelled states.

- The pressure loss across a pipe and the flow through it, must share sign in their values. Otherwise, the potential energy contained in the pressure is in opposition to the current exerted by the water, which violates the assumption of the pressure model.

- The sum of flows over each node, which can have any number of connecting pipes, must be exactly zero, to preserve the mass balance of the system. The only exception is for elevated storage, which does have an accumulating capacity.

- The sum of all flows entering and leaving a pressure zone must also be zero, with the exception to the elevated storage. When verifying this, it is useful to consider the connecting pipe(s) to the storage tank as a boundary condition.

- The sum of all flows across a storage tank must equal the derivative of the volume (i.e., the volume change over time).

Model elements¶

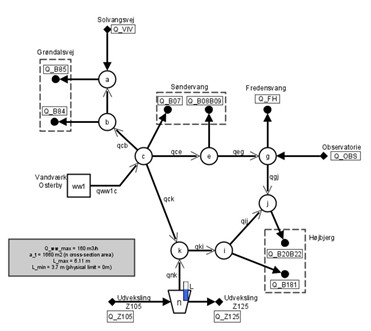

The model is designed as a graph, with links and nodes, that are defined by how they connect and interact. There are two additional types of nodes; nodes with a storage capacity, and nodes with externally set pressure.

The nodes and links model the representation of the physical properties. Another set of elements define the behaviour of the controller.

This division is made such that it is possible to use the model without controller parameters. The following processes utilises the model without control:

- Solve the massbalances across a district, to verify measurements and create states for simulation.

- Parameter identification.

- Hindcasts to quantify how well the model fits.

Node¶

Nodes are a representation of a junction. The model state for a node is pressure. In the model predictive control program, the nodes contribute as points with known pressure. Also, each node is a junction across which a massbalance must be solved, depending on the links that connects to it.

The network should have at least one node with externally set pressure, which would for instance be a waterworks.

The node has the following properties:

- lateral flow. The generalised termfora demand. This is for streams that go into or out of the model.

- bias. If the node is not directly associated to a sensor, bias is used to correct the elevation to nearest sensor.

- area. Setting this parameter, creates a reservoir at the node. There is no volume parameter, as minimum and maximum level are taken as control parameters.

Link¶

Links are a representation of a pipe or series of pipes for 1 stream. It covers any distance between two junctions or nodes. A link can't have branches, only exactly one source node and sink node. In the program, the link represents a flow.

The link has the following properties:

- from node. The source node for the link.

- to node. The sink node for the link.

- alpha. A parameter of generalised resistance for the pipe.

Control elements¶

The elements that define (parts of) the control strategy Any element can be extended with a control element of an appropiate class. This separates control properties from the core model:

- As described above, the core model, has applications that should not require a control strategy.

- The control model is expected to update each time it is executed, while the core model is supposed to be more or less constant.

Control node¶

Append a minimal pressure constraint to a node in the network.

Tank¶

Add a tank model to a node in the network. It is defined with minimum and maximum levels, as constraints, and a target water level in the cost function.

Pump¶

Add a pump model to the network. The pump class is associated with both a node and a link. The pump is described with both a pressure state, and a flow state. The flow and pressure states are constrained by an approximation of the system characteristics. A pump is defined by its capacity, and can be assigned a minimal flow as well. Pumps are part of the cost function; it is a control objective to maintain a stable discharge flow, both because it is a better way to operate the pump, and it provides opportunity for a stable water production in the well fields.